A Complete Guide to Aluminium Sheets and Their Uses in Modern Industries

Aluminium sheets play a vital role in the world of manufacturing. Their versatility, strength, and adaptability make them one of the most widely used raw materials across countless industries. From construction and packaging to automobiles and home appliances, aluminium sheets are an essential component in forming durable and high performance products.

Why Aluminium Sheets Are Widely Used

Aluminium sheets offer several valuable characteristics that make them suitable for a variety of applications.

Strength and Structural Reliability

Aluminium sheets provide excellent strength for construction, architectural work, and industrial structures.

Corrosion Resistance

Aluminium naturally resists corrosion, which increases the lifespan of any product created using it.

High Reflectivity

The reflective surface of aluminium makes it ideal for lighting, insulation, and decorative purposes.

Easy to Machine and Form

Aluminium can be shaped, cut, drilled, and machined with ease, allowing manufacturers to create precise components.

Impermeable and Odorless

Its non porous and clean properties make it suitable for food packaging and hygienic environments.

Flexible in Design

Aluminium sheets can be transformed into countless shapes using modern fabrication technologies.

100 Percent Recyclable

Aluminium is one of the most recyclable materials in the world, promoting sustainable manufacturing.

How Aluminium Sheet Fabrication Works

The fabrication process begins with raw aluminium sheet material, which is shaped into specific parts through forming, deforming, or material removal techniques. The thickness of the sheet varies depending on the application and the grade of metal being used.

Advanced tools such as cutting saws, torches, bending equipment, and rolling machines are used to shape aluminium sheets into the desired form. For example:

- Rolling machines help form round or curved sections.

- Cutting tools and torches are used to trim large sheets with precision.

- Welding is used to join fabricated parts securely while preventing issues like warping.

Once the fabrication is complete, the metal can be finished with coatings such as paint, powder coating, or plating to enhance appearance and durability.

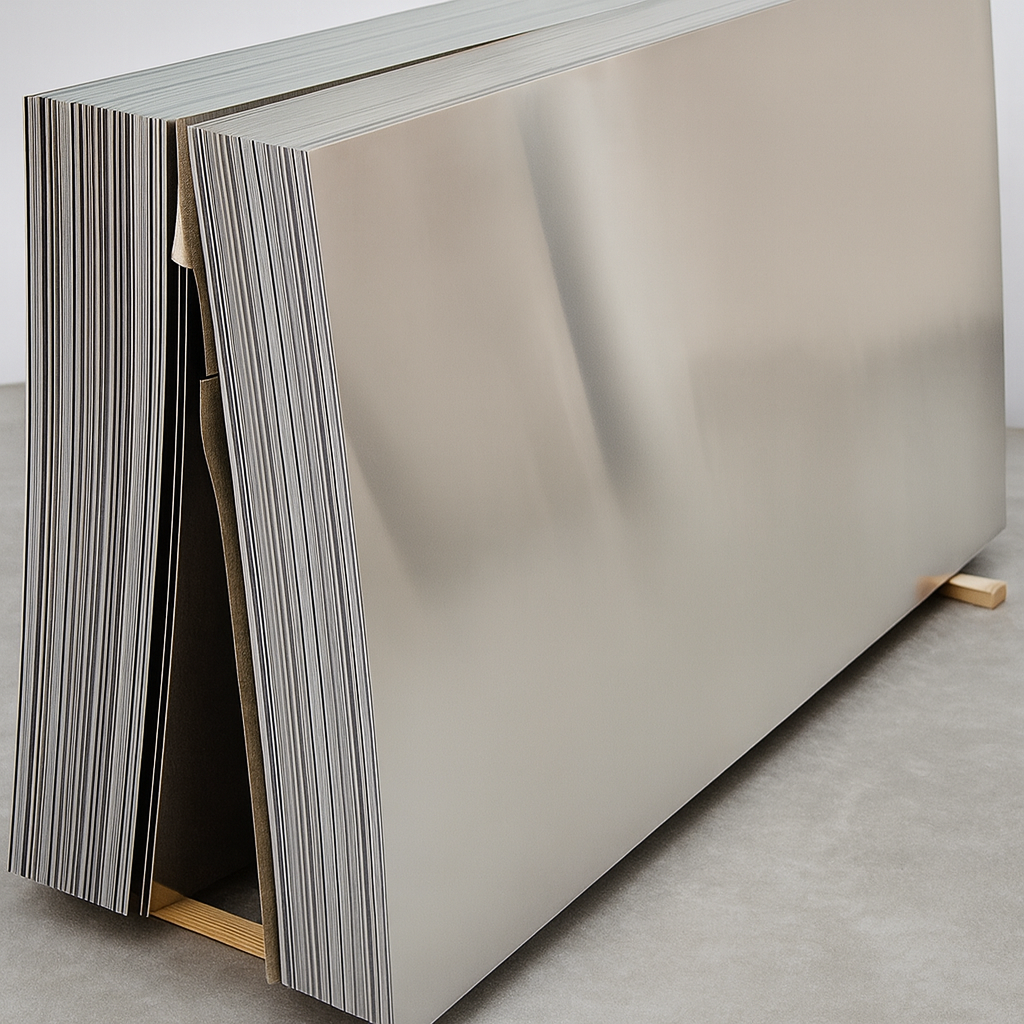

Difference Between Aluminium Sheets and Aluminium Plates

As aluminium passes through rolling mills, it becomes longer and thinner. The thickness achieved determines whether the product is classified as a sheet or a plate.

Aluminium Sheets

Typically have a thickness below 0.6mm and are used for lightweight applications such as cladding, packaging, and interior finishes.

Aluminium Plates

Have a thickness of 0.6mm or more and are used for heavy duty applications including structural components, marine work, aerospace parts, and industrial machinery.

Although both serve different purposes, they share the same advantages of durability, corrosion resistance, and versatility.

Aluminium Sheets and Plates from IBM UAE

IBM UAE supplies high quality aluminium sheets, plates, and various aluminium products tailored to meet the needs of industrial, commercial, and construction sectors. Our commitment to quality ensures you receive reliable materials that support long lasting performance across all types of projects.

Whether you require aluminium for fabrication, architectural work, machinery, or general manufacturing, IBM UAE offers materials designed to meet your specifications with excellence.